Introduction to Metal Stamping Dies

Definition and Purpose

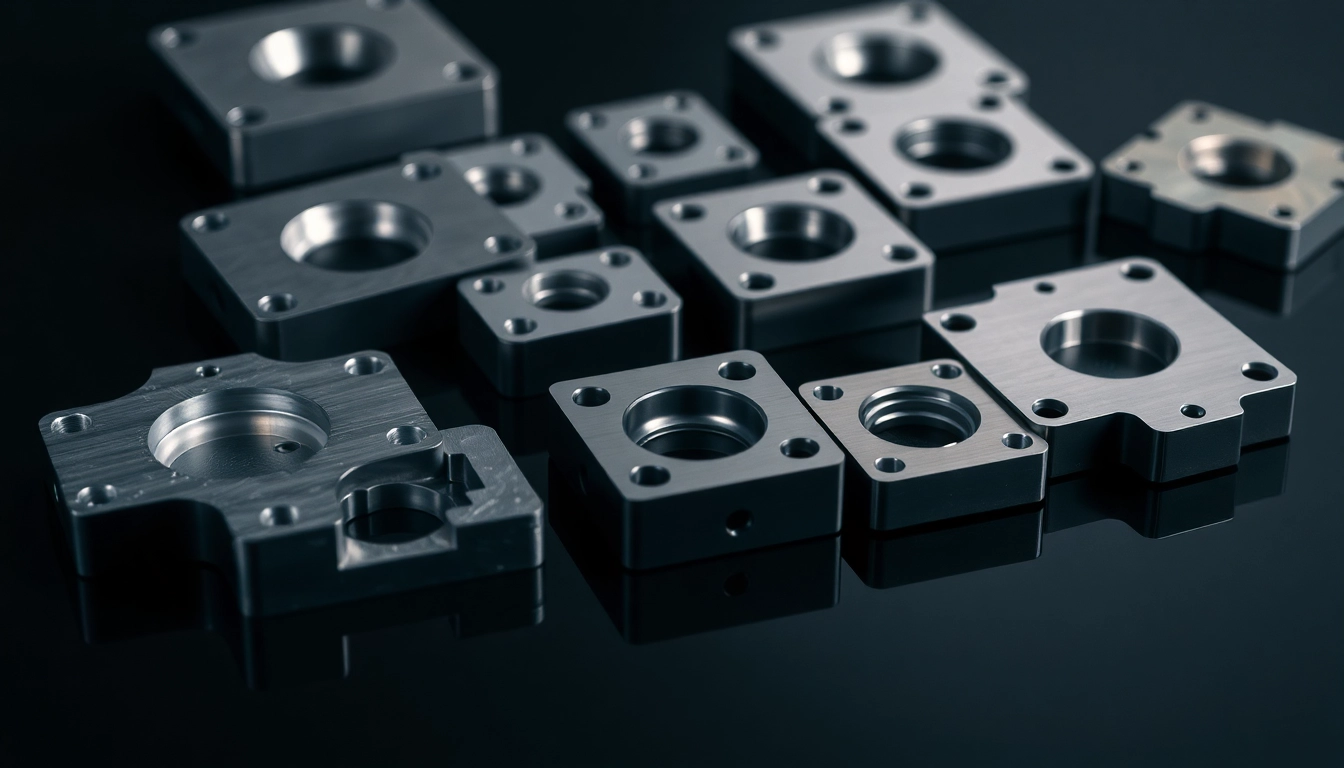

Metal stamping dies are essential tools in manufacturing that facilitate the shaping and forming of metal into desired structures and components. These dies play a pivotal role in various industries, enabling the mass production of intricate parts with high precision and repeatability. The fundamental purpose of metal stamping dies is to mechanically deform metal sheets through cutting, bending, and shaping processes, resulting in finished components that meet stringent quality standards.

In essence, these dies act as molds that ensure uniformity and accuracy, from small electronic connectors to large automotive parts. This critical role underlines the importance of high-quality metal stamping dies, like those available at Metal Stamping Dies, designed to excel in various applications across different sectors.

Overview of Applications

Metal stamping dies are utilized in a wide range of applications, making them indispensable in modern manufacturing. Their versatility allows them to serve numerous functions such as cutting, forming, and assembling parts, which can be found in automotive, electronics, industrial machinery, home appliances, and even medical devices.

For instance, in the automotive industry, these dies are employed to fabricate complex shapes for vehicles, such as brackets, clips, and battery terminals. In the electronics sector, they produce precision parts like sensor housings and circuit components. The high adaptability of metal stamping dies ensures they meet the varied demands of such diverse fields.

Key Industries Utilizing Metal Stamping Dies

Several key industries rely heavily on the capabilities of metal stamping dies:

– Automotive Industry: This market requires high precision components for vehicles, including chassis, body parts, and electrical fittings. Metal stamping dies are crucial in achieving the durability and accuracy needed for automotive applications.

– Electronics: As demand for electronic devices increases, so does the necessity for intricate metal parts. Precision dies help manufacture parts such as connectors, circuit boards, and housings with the utmost accuracy.

– Industrial Manufacturing: Metal stamping dies are instrumental in producing machine parts and structural components, enabling efficiency and consistency in industrial production lines.

– Home Appliances: Whether it’s metal housings or internal components, metal stamping plays an essential role in the assembly of home appliances, ensuring both functionality and aesthetic appeal.

Key Features and Advantages

High-Quality Material Options

The material quality of metal stamping dies significantly influences their performance and longevity. At our facility, we employ high-grade tool steel options such as SKD11, ASP23, DC53, and tungsten carbide. These materials demonstrate exceptional hardness, wear resistance, and durability, ensuring that our dies can withstand extensive production runs without compromising their integrity.

Moreover, our customers can specify custom alloys tailored to their particular needs, enhancing the performance characteristics of the dies further. The careful selection of materials plays a crucial role in maintaining the precision and reliability necessary for high-stakes applications across various industries.

Longevity and Reliability

One of the standout advantages of our precision dies is their longevity. Crafted with exceptional materials and design precision, these dies are capable of enduring over one million strokes, depending on the specific materials and processes employed. This extended lifecycle not only reduces production costs but also mitigates the frequent need for replacements or repairs.

Longevity is bolstered by our in-house heat treatment processes and surface finishing options such as mirror polishing, nitriding, and PVD/CVD coatings, which enhance the wear resistance of the dies.

Precision Manufacturing Techniques

Our approach to manufacturing precision dies involves advanced methodologies that guarantee unmatched accuracy. We utilize EDM (Electrical Discharge Machining) and CNC (Computer Numerical Control) grinding technologies, which enable us to create dies with tight tolerances of ±0.005 mm, potentially customizable to ±0.002 mm.

These high-precision manufacturing techniques ensure that every die we produce maintains stable dimensions and achieves perfect forming with minimal burrs—critical factors for industries where precision is paramount.

Application Areas for Precision Dies

Automotive Components

The automotive industry significantly benefits from the application of precision stamping dies. They are pivotal in the fabrication of various components such as brackets, battery terminals, and connectors that are integral to vehicle construction. Our dies are designed to handle complex shaping tasks, and they ensure that automotive parts fit seamlessly and function reliably under stress and strain.

Each die tailored for automotive applications undergoes stringent testing to meet industry specifications, ensuring that safety and performance standards are always upheld.

Electronics Industry Uses

Precision stamping dies are invaluable in the electronics sector, where components often need to be compact and intricately designed. Our dies facilitate the production of microelectronic connectors, sensor housings, and other essential components needed for modern electronic devices.

With the rapid advancement of technology, our custom die design capabilities allow for innovation in electronic components, accommodating bespoke specifications and improving overall device performance.

Industrial and Home Appliance Applications

The production of home appliances and industrial machinery benefits tremendously from precision stamping dies. For industrial applications, these dies manufacture metal enclosures, machine parts, and structural components, ensuring that products are robust and durable.

In the context of home appliances, from decorative housings to functional brackets, our stamping dies provide the exact requirements for performance and aesthetic appeal. The reliability and precision offered by our dies contribute significantly to the efficiency and functionality of appliances used daily.

Customization and Support Services

Tailored Design Options

Understanding that each customer may have unique requirements, we offer tailored design options for our precision dies. Our dedicated design team collaborates closely with clients to create custom die design kits that align with specific drawings and production needs.

This flexible approach not only empowers clients to achieve their desired outcomes but also ensures that the designs support the intended manufacturing processes effectively.

Small Batch Trials and Expedited Services

We recognize that customers may wish to test the viability of their designs before committing to large-scale production. Hence, we offer support for small batch trials, which allow clients to evaluate the performance of the dies under actual production conditions.

In addition, we understand that timelines can be tight; thus, we also provide expedited services to accommodate urgent projects. Typical lead times are between 3-6 weeks, depending on the complexity and materials involved, ensuring that your production schedules are met without unnecessary delays.

Design Review and Troubleshooting

Ensuring optimal performance of metal stamping dies is crucial, which is why our engineers are available for comprehensive design reviews and process recommendations. Should any challenges arise during production, our team is equipped to provide troubleshooting guidance, helping customers address potential issues proactively.

This ongoing support guarantees that our clients receive not only the highest quality dies but also exceptional service throughout their manufacturing journey.

FAQs About Metal Stamping Dies

Common Questions and Expert Answers

As with any specialized equipment, queries related to metal stamping dies often arise. Below we’ve compiled answers to some of the most frequently asked questions:

– What is the typical lifespan of a precision die?

Most precision dies can last up to one million strokes depending on the material used and the operational conditions. Our customer support team can assist you with specifics based on your die selection.

– Can I customize my die design?

Yes, we offer customization options to suit your specifications. Our team will work directly with you to ensure your dies meet your particular requirements.

Maintenance and Lifespan Queries

Regular maintenance of your metal stamping dies is essential to prolong their lifespan. Clients are encouraged to observe best practices such as proper cleaning, lubrication, and regular inspections to maintain die performance.

This maintenance not only ensures the longevity of the dies but can also enhance the quality of the produced parts by minimizing wear and tear.

Contacting Support for Custom Needs

If you have specific production needs or questions about our precision dies, our supportive team is always available. Whether it’s about customization, application advice, or any other inquiries, contacting us helps ensure that you receive comprehensive support tailored to your needs.

Our commitment to customer service ensures that your manufacturing processes are smooth and efficient while using our precision metal stamping dies.